Ultra Low Charge With Direct Expansion

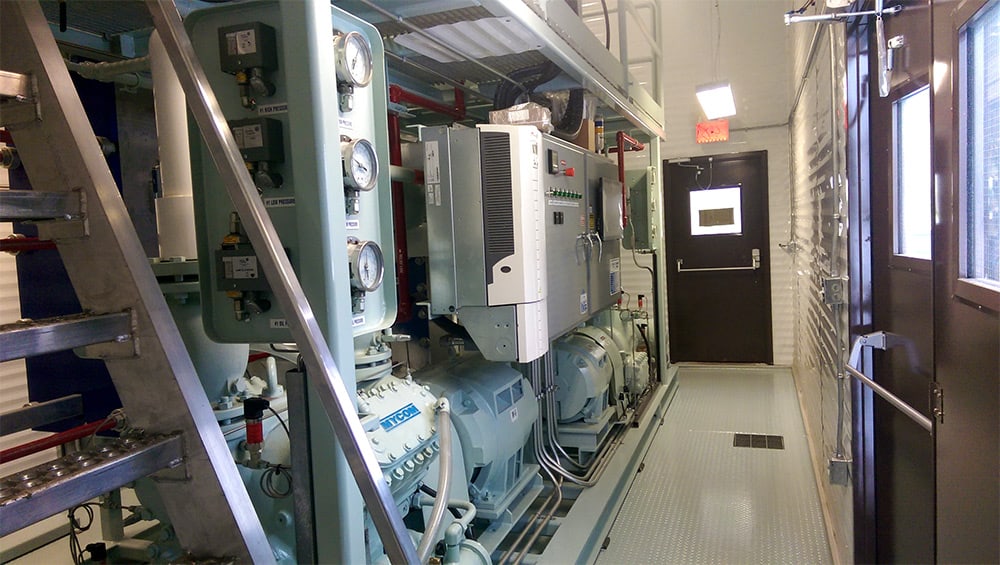

The new EZ ICE ADX skid packages, developed by Ultimate Fabrication, are designed to take advantage of Anhydrous Ammonia as a refrigerant by utilizing direct expansion, resulting in an ULTRA LOW refrigerant charge.

Utilizing Ammonia Direct Expansion (ADX), these systems can achieve approximately 1/2 to 3/4 lbs per ton of refrigeration. Traditional ammonia flooded systems require 5 to 10 lbs of refrigerant per ton of refrigeration. With our EZ ICE ADX system, we can achieve the same tonnage with 1/8 of the system charge!

- EZ to install, EZ to operate, EZ to maintain and EZ to service.

- Ultra Low ammonia charge!

- Water, ethylene or propylene glycol can be used for condenser loop:

- Condenser loops are used for the Snow Melt Pit (SMP) system

- Heat floor system. Option to have separate heat exchange to convert existing heat floor system to brine if required.

- All NH3 piping completed on skid. Ne external NH3 piping required.

- Meets Technical Standards and Safety Act (TSSA) 2006 R6 rating.

- Motor Control Centre (MCC) with all compressor safeties, starters, overloads, relays and timers in a CSA type 12 cabinet mounted on the skid package.

- All motors are completely wired within the skid.

- Compressors are direct drive with Variable Frequency Drive (VFD) control.

- The ADX packages are available in different capacities.

- Standard Digital Direct Controller (DDC) included (with many options to expand).

- A service-friendly skid package designed to allow for easy access to all maintainable components.

- Options to choose upon request:

- Heat floor system.

- Snowmelt pit system.

- Domestic water preheat system.

- 100% back-up pump completely piped in ready for automatic switch over.

- Expandable Digital Direct Controller (DDC) system.

- Handrail and catwalk for maintenance of elevated equipment with removable aluminum ladder.

20’ – 0” (6096 mm) Long

10’ – 6” (3200 mm) High

*Dimensions may vary based on final design.

**Shipping weight may vary based on final design.

*Full Amperage of skid package is only for motors listed in performance specifications data. Final amperage of skid package is confirmed at time order is placed and optional items secured.

**Total HP of skid package includes only motors listed in performance specifications data and does not include optional items. Final HP of skid package will be determined at time of order.

***Motors not included in performance specification chart as they are option items only and need to be confirmed at time of order. HP ratings could change.

95° F SCT

- Features

-

- EZ to install, EZ to operate, EZ to maintain and EZ to service.

- Ultra Low ammonia charge!

- Water, ethylene or propylene glycol can be used for condenser loop:

- Condenser loops are used for the Snow Melt Pit (SMP) system

- Heat floor system. Option to have separate heat exchange to convert existing heat floor system to brine if required.

- All NH3 piping completed on skid. Ne external NH3 piping required.

- Meets Technical Standards and Safety Act (TSSA) 2006 R6 rating.

- Motor Control Centre (MCC) with all compressor safeties, starters, overloads, relays and timers in a CSA type 12 cabinet mounted on the skid package.

- All motors are completely wired within the skid.

- Compressors are direct drive with Variable Frequency Drive (VFD) control.

- The ADX packages are available in different capacities.

- Standard Digital Direct Controller (DDC) included (with many options to expand).

- A service-friendly skid package designed to allow for easy access to all maintainable components.

- Options to choose upon request:

- Heat floor system.

- Snowmelt pit system.

- Domestic water preheat system.

- 100% back-up pump completely piped in ready for automatic switch over.

- Expandable Digital Direct Controller (DDC) system.

- Handrail and catwalk for maintenance of elevated equipment with removable aluminum ladder.

- Skid Specs

-

SKID DIMENSIONS*7’ – 6” (2286 mm) Wide

20’ – 0” (6096 mm) Long

10’ – 6” (3200 mm) High

SHIPPING WEIGHT**23,600 lbs (10,727 kg)OPERATING WEIGHT26,600 lbs (12,090 kg)NH3 CHARGE60 lbs (27 kg)*Dimensions may vary based on final design.

**Shipping weight may vary based on final design. - Electrical Specs

-

SUPPLY VOLTAGE575V / 3Ph / 60Hz460V / 3Ph / 60HzFULL LOAD AMPS (FLA)*181 Amps226 AmpsTOTAL MOTOR HP OF SKID**160.5 HP160.5 HPCOMPRESSOR #1 MOTOR50 HP50 HPCOMPRESSOR #2 MOTOR100 HP100 HPCOOL PUMP MOTOR30 HP30 HPJACKET COOL PUMP MOTOR1/2 HP1/2 HPCOND GLYCOL PUMP10 HP10 HPFLUID COOLER FAN MOTORTBDTBDFLUID COOLER WATER PUMPTBDTBDHEAT PUMP MOTOR***3 HP3 HPSNOWMELT PIT PUMP MOTOR***3 HP3 HP

*Full Amperage of skid package is only for motors listed in performance specifications data. Final amperage of skid package is confirmed at time order is placed and optional items secured.

**Total HP of skid package includes only motors listed in performance specifications data and does not include optional items. Final HP of skid package will be determined at time of order.

***Motors not included in performance specification chart as they are option items only and need to be confirmed at time of order. HP ratings could change. - Performance Specs

-

SYSTEM TONNAGE100 TRDESIGN CONDITION10° F SST

95° F SCTPRIMARY REFRIGERANTR-717 Ammonia (NH3)SECONDARY REFRIGERANT21% CaCl2 – Calcium ChlorideCOMPRESSORSMycom 2M & 4M ReciprocatingQUANTITYOne 2M & One 4MTONS PER COMPRESSOR2M = 37.5 TR / 4M = 71.7 TRBRAKE HORSEPOWER2M = 48.4 BHP / 4M = 89.1 BHPCHILLERPlate & Frame – DXCOOL FLOOR PUMPArmstrong 4030 – 6x5x10 – 30 HPFLOW & PD850 USGPM @ 36 PSIGCONDENSERPlate & FrameCONDENSER GLYCOL PUMPArmstrong 4280 – 4x3x10 – 10 HPFLOW & PD337 USGPM @ 25 PSIG - Gallery